World-Class UK Contract Electronics Manufacturing

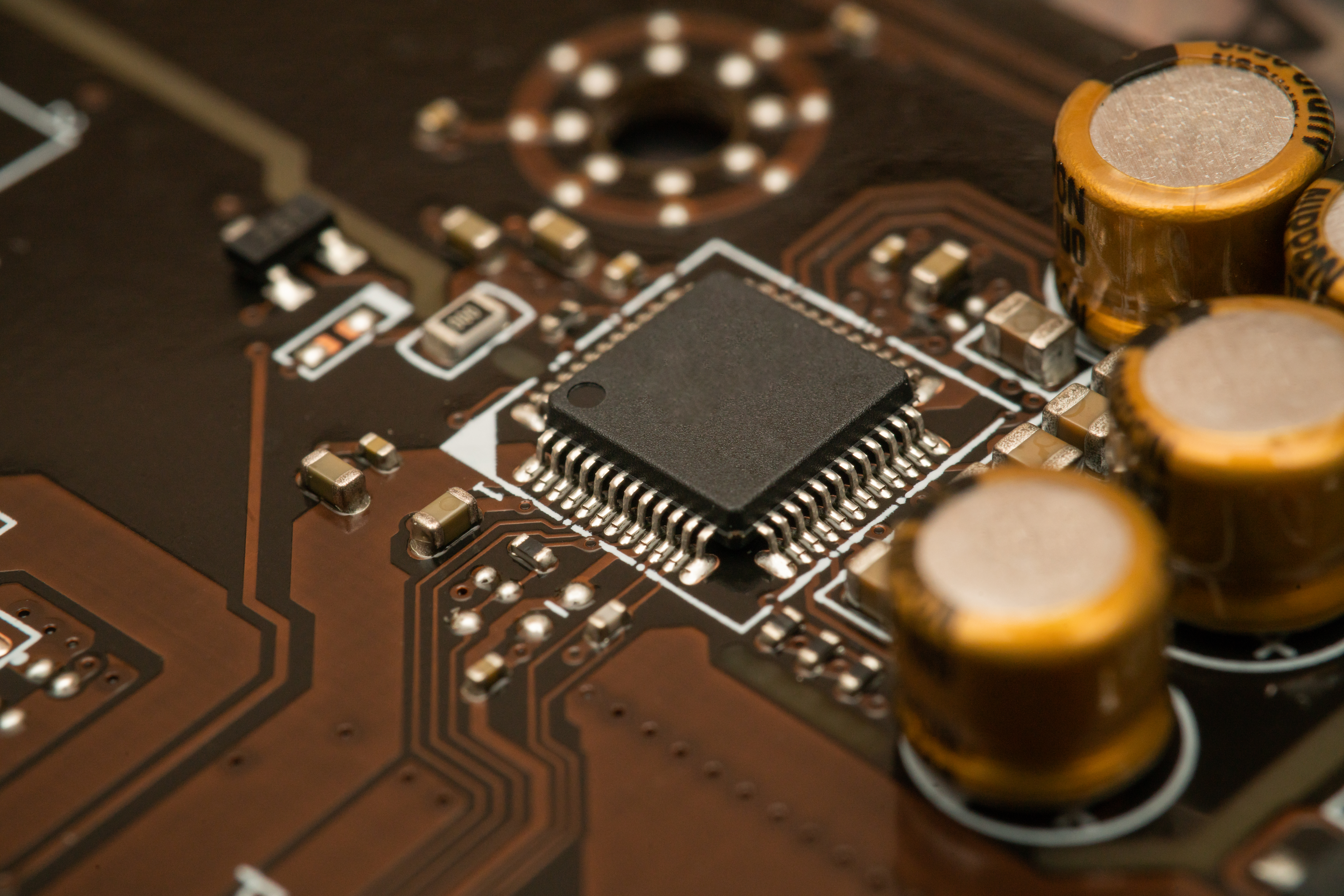

UK CEM delivering prototype to medium volume PCB assembly, LED assembly, box build, cable harnessing, testing and turnkey solutions.

ABOUT LCL ELECTRONICS ASSEMBLY

We produce, assemble and test printed circuit boards (PCBs) to the highest quality for a wide range of clients, including many blue chip companies.

From rock ‘n’ roll to rolling stock, our PCBs are used and trusted in global industry sectors as diverse as, audio education electronics, leisure, fire safety, signalling, LED lighting, medical diagnostics and rail.

Investing in the latest technology and equipment ensures we remain at the forefront of PCB technology, including LED assembly capabilities. This includes the ability to place components as small as 01005 through to BGA and micro BGAs.

SERVICES

Expert DFM analysis optimises your designs for efficient, cost-effective manufacturing before production begins

Tailored LED assembly with customised tools, processes, and testing for optimal performance.

Complete turnkey solutions from sourcing to final testing and packaging. Single supplier, faster time-to-market.

Custom cable assembly and wire harnessing for a wide range of applications, ensuring robust and reliable connections.

Managed supply chain reduces costs and mitigates risks without compromising quality. Authentic components guaranteed.

Your Complete Manufacturing Partner

As your dedicated contract electronics manufacturing partner, we handle everything from initial prototype through to final dispatch — covering PCB assembly, testing and delivery all under one roof. This streamlined approach ensures your product is built for performance and market success, all from our UK-based facility

SERVICES VIDEO

When forward-thinking companies need a trusted manufacturing partner to transform ambitious electronic projects into commercial success, LCL Electronics becomes their strategic ally. Our three-decade journey through the evolving electronics landscape has taught us that exceptional products emerge from the perfect fusion of technical mastery and genuine partnership. Operating from our purpose-built Leicestershire facility, we’ve become the manufacturing backbone for visionary businesses across medical technology, transportation systems, entertainment platforms, and next-generation lighting solutions.

What sets us apart isn’t just our comprehensive turnkey approach – it’s our ability to seamlessly bridge the gap between your creative vision and market-ready reality, handling every complexity from initial prototype through full-scale production while you focus on what you do best: growing and scaling your business.

REVIEW

We’ve worked with Alan, Andy, and the team at LCL for over six years, drawing on their expertise from design and prototyping through to high-volume production. Their technical capability and consistency make them a valued partner in our development process.

Robert, Operations Manager

Trusted by Industry Leaders

Powering global industries from rail and medical diagnostics to professional audio and LED lighting.

We’ve worked with Alan, Andy, and the team at LCL Electronics Assembly for over six years, drawing on their expertise from design and prototyping through to high-volume production. Their technical capability and consistency make them a valued partner in our development process.

Robert Operations Manager