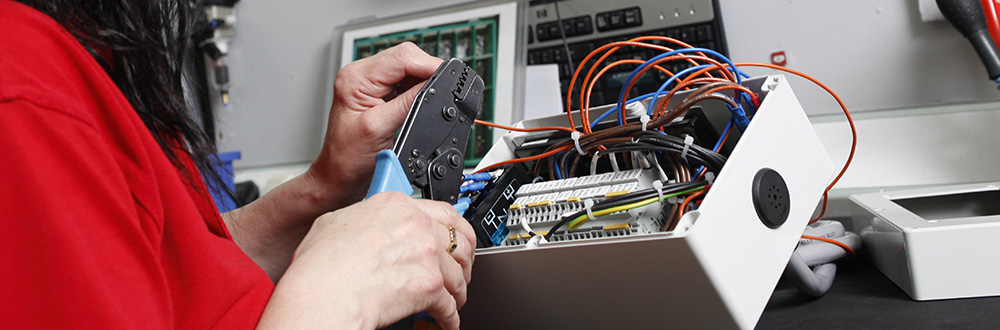

With our full Box Build service we manage the entire operation, from component and PCB procurement, through PCB and mechanical assembly, to full box build, final test, packing and dispatch.

Working in close partnership with our customers, we develop a strategy which enables us to provide a quality finished product every time.

We can test the products to your individual specifications, or our in-house software team can develop test routines specifically for each project. As we build the test rigs we can ensure the sub-assemblies and the final build products all operate to the full specifications at every stage of manufacture.

Our long term relationships with manufacturing partners, both in the UK and worldwide, mean we have access to some of the best designers, precision metal workers, plastic injection toolmakers and PCB manufacturers. All of this ensures continuity of supply and quality, to give you a professional finished product.

When you choose LCL Electronics Assembly as your turnkey manufacturing partner you are accessing not only our expertise in manufacturing, but the full benefit of our drop ship distribution and warehousing facilities.

A major factor of using LCL Electronics Assembly is budget control. Each unit you buy is at a fixed cost. You no longer have to factor waste materials into your costs, as you would if you were manufacturing yourself. Major savings in fixed and variable costs are also made, including wages, holiday pay, sick leave, maternity leave etc. No longer do you have to factor in massive overhead costs, such as rent and rates for office, factory and warehouse space. We take away all of those worries. Plus our continual reinvestment in new equipment, technology and people means you always have access to one of the finest manufacturing facilities in the country.