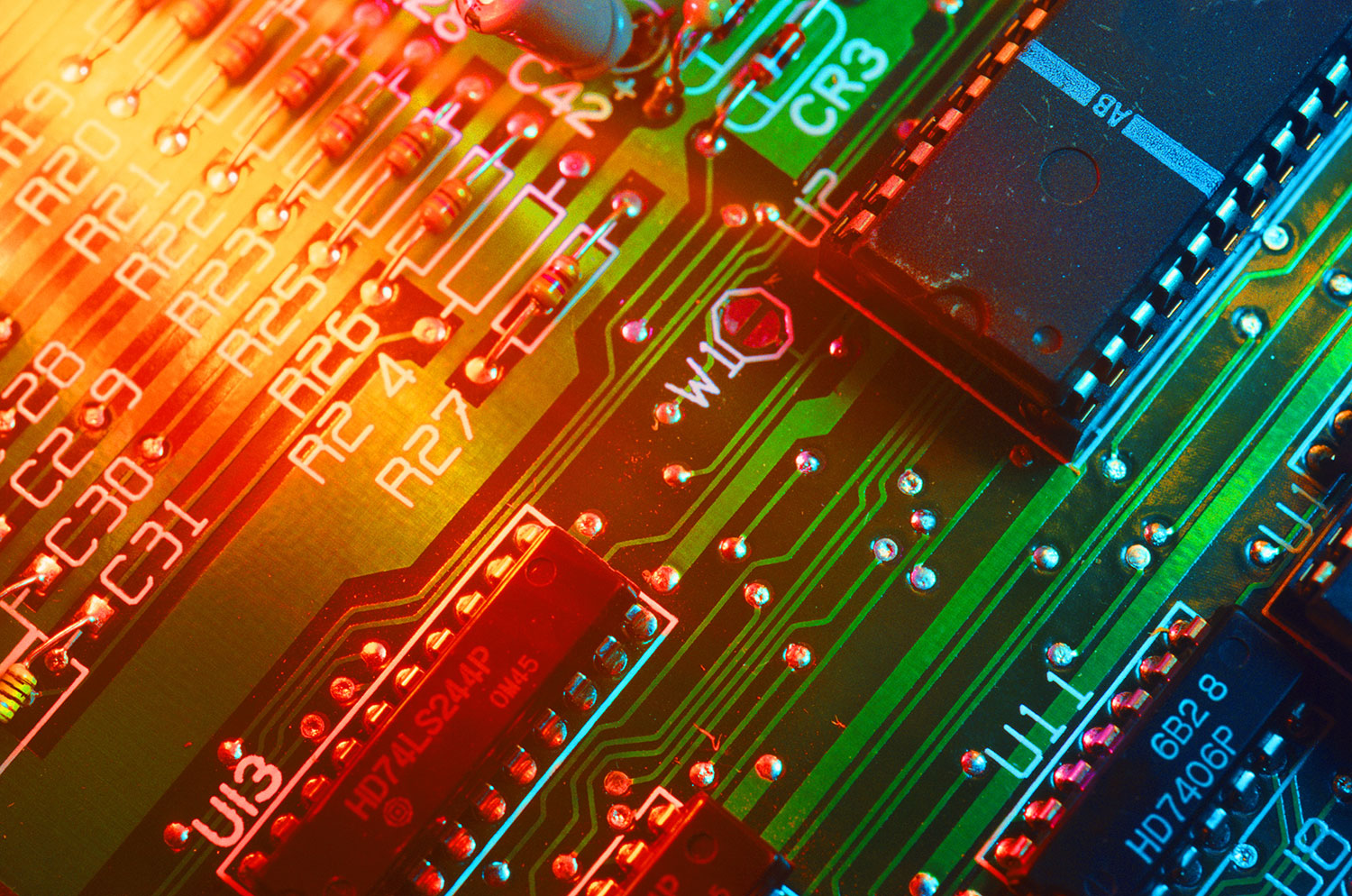

Established in 1992, we have seen considerable growth in production requirements, from offering electronic assembly services (PCB assembly, SMT, box build) to include cable and harness assembly. This required us to consider our production control planning and processes to efficiently manage increased orders and deliver them on-time, and to budget.

Following the installation of a production planning and control system, plus staff training and improved internal processes, we have been able to increase efficiency in data capture and scheduling. This has provided foresight into orders and production, allowing us to incorporate new orders into the system so that the team can see what is required, when it is required by and what orders are coming up. This is becoming increasingly important as the company grows.

The system also allows us to create different scenarios which in turn has led to a reduction in lead times, with maximum throughput. Full visibility of production activities allows the management team to see performance data quickly, and allow them to adapt and change fast if necessary, in order to meet production requirements.

If you want to find out how LCL can help you improve your production times and potentially reduce costs contact Mark Harbord on +44 (0) 116 260 6171 or email mharbord@lclelectronics.co.uk.