FAQ

Frequently Asked Questions

Have a question? We’ve compiled answers to some of the most common queries we receive. If you don’t find what you’re looking for, please contact us.

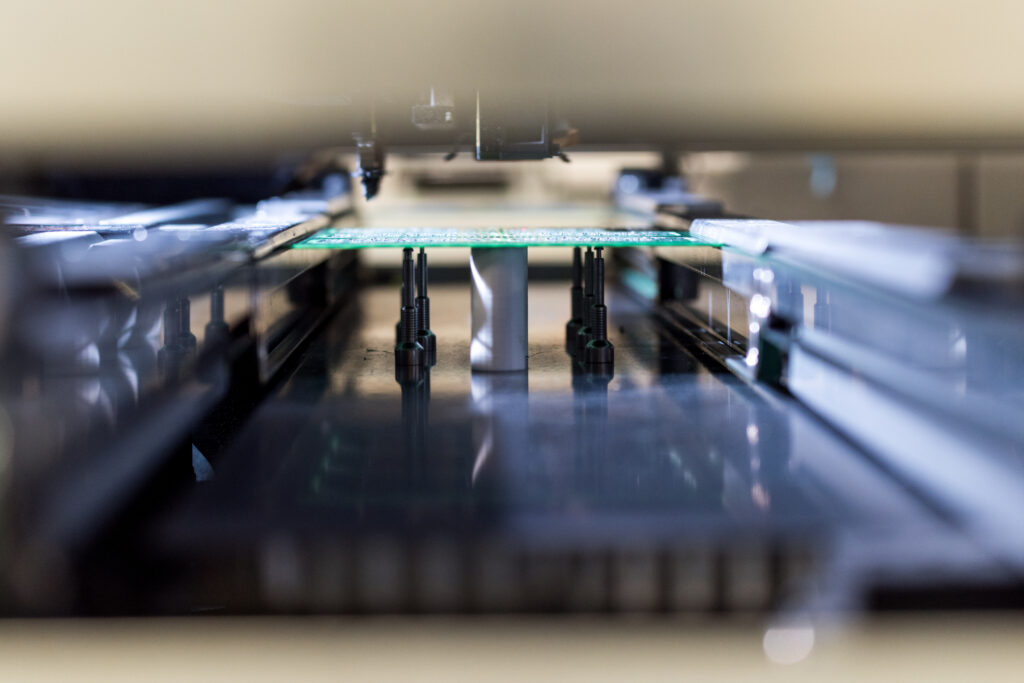

We offer complete electronics manufacturing services, including PCB assembly, cable harness assembly, box build, testing, supply chain management and Design

Yes, we support everything from low-volume prototyping through to high-volume production.

We can fully manage component sourcing, or work with free-issued parts supplied by clients.

We manufacture for Audio, Fire Signalling, automotive, medical, LED Lighting, Lighting control, industrial, consumer electronics.

Our machines can handle a maximum size PCB of 1200mm long by 500mm wide.

We offer SMT, through-hole, mixed technology, double-sided assembly, and fine-pitch/BGA capabilities.

Yes, our engineers assist with PCB layout, prototyping, and Design for Manufacture (DFM).

Typically Gerber files, a Bill of Materials (BOM), and assembly drawings.

Yes, full material and process traceability can be provided to meet compliance requirements.

We proactively monitor supply chains, suggest alternatives, and work with global suppliers to secure parts.

We operate under ISO9001 and follow IPC-A-610 standards. Additional certifications can be supported as required.

Yes, all processes are compliant with RoHS and REACH.

We use AOI, in-circuit testing, functional testing, and custom test solutions.

Yes, we can test using client provided test equipment, alternatively we can work with our clients to develop in circuit or full functional testing.

Yes, we provide conformal coating, potting, and encapsulation for protection in demanding environments.

Yes, we provide full integration, including enclosures, wiring, labelling, and packaging.

We supply everything from simple cut-and-strip wires to complex wiring looms and harnesses.

Yes, we offer rework, repair, and refurbishment to extend product life.

Yes, we manufacture for clients in the UK, Europe, and worldwide, with logistics support for shipping.

Lead times vary depending on complexity and materials, but we always aim for fast-turn prototypes and reliable scheduling.